Benelux

United Kingdom

India

Slovakia

USA

Mexico | EN

Contact

Downloads

Benelux

United Kingdom

India

Slovakia

USA

Benelux

United Kingdom

India

Slovakia

USA

Hydrogen is one of the key elements when it comes to climate neutrality and the transition to clean energy. With our pipeline elements and systems, we support you wherever hydrogen needs to be conveyed from point A to point B.

With over 30 years of experience in various hydrogen applications, we are experts in the safe conveyance of hydrogen. As a competent development partner, we support you with our technical expertise and innovative solutions.

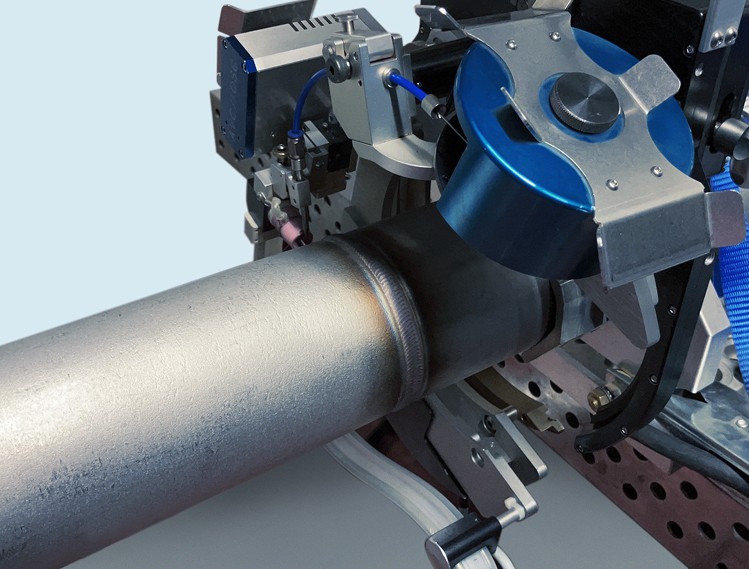

The perfect weld seam requires precision preparation. Burr-free and gap-free welding can significantly reduce stress corrosion cracking, notch stress and hydrogen corrosion. Our established welding processes are

Our pipelines are tested under realistic conditions. We use all common test methods, such as

In our laboratories, we test every material according to the required properties. After extensive testing, our experts have come up with a ranking system that recommends materials for use with hydrogen depending on the application.

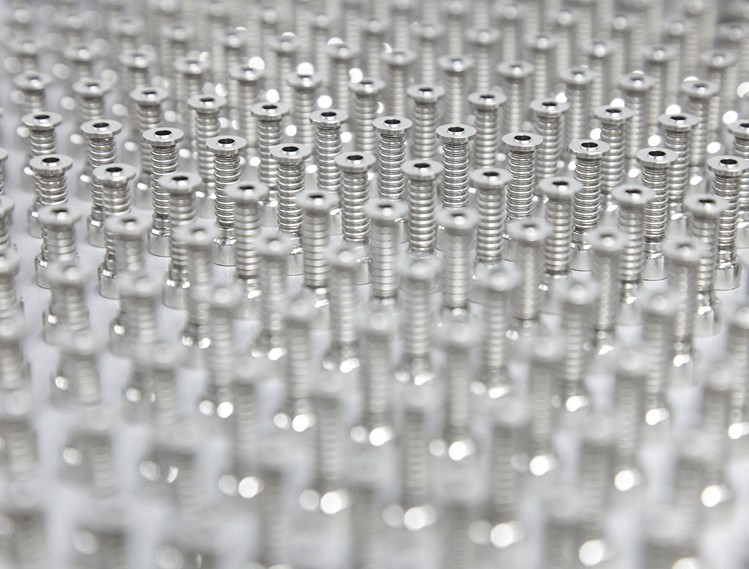

Our products are always put to use when a connection from A to B is required. We develop customised solutions, always designing them according to our customers' requirements.

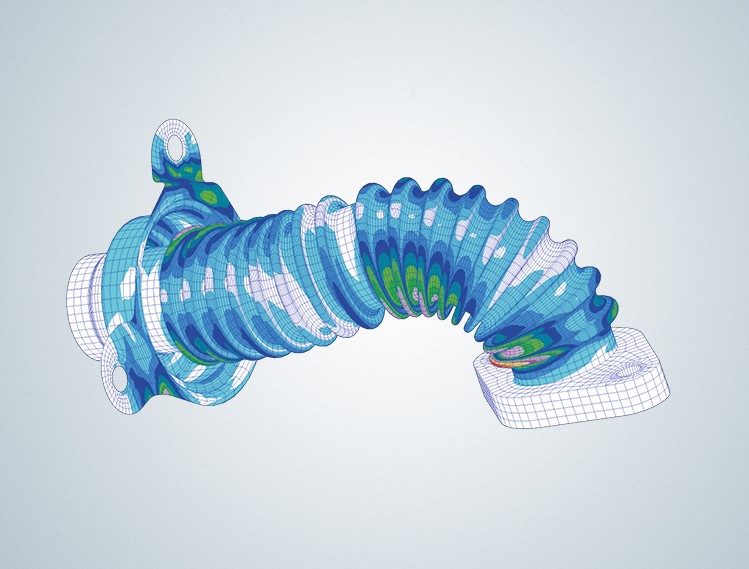

As a development partner, we support our customers and partners at every stage - from brainstorming to the finished application. In doing so, we benefit from our interlocking process chain across multiple levels.

Our pipework systems are safe, durable and of the highest quality. This is also underscored by our certifications:

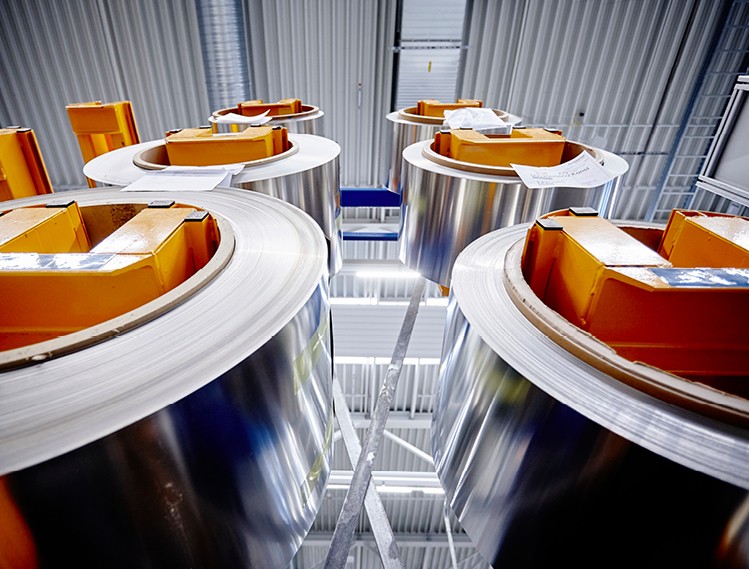

With our processes and production capacities, we are equipped to develop customised solutions from small to large series with

From the production, storage and transport of hydrogen to its use in industry and mobility, we will be at your side as a development partner. Our flexible and rigid elements are put to use all along the hydrogen value chain.

Strategic partnerships help by combining forces and expanding our own knowledge in order to create new solutions. That is why we are an active member of alliances and collaborate in research programmes.

Green hydrogen

is produced by the electrolysis of water. The electricity required for this comes from renewable energy sources such as solar, wind and hydroelectric power. For this reason, production is CO2-neutral and therefore climate-friendly.

Gray hydrogen

is produced from fossil fuels such as natural gas, coal or oil by steam reformation. Ten tonnes of CO2 are produced as a waste product for when producing one tonne of hydrogen. It is not climate-neutral.

Blue hydrogen

is produced, as with grey hydrogen, by steam reformation. However, the CO2 released is stored underground (CCS technology: Carbon Capture and Storage). Since the CO2 is not released into the atmosphere, blue hydrogen is effectively CO2-neutral.

Turquoise hydrogen

is produced during methane pyrolysis. Natural gas (methane) is split into hydrogen and solid carbon in a thermochemical process. The solid carbon can be stored as granulate and reused at a later date.

Red/pink hydrogen

is produced by electrolysis, just like green hydrogen. However, the necessary electricity comes from nuclear energy. Therefore, while this type of hydrogen is CO2-neutral, it produces radioactive waste that has to be stored safely.

There are numerous technologies available for producing hydrogen. Today, it is mainly obtained by steam reforming of fossil fuels, which also produces CO2. One process that is becoming increasingly important due to its climate neutrality is electrolysis. In this process, water is split into its components hydrogen and oxygen using electricity from renewable energy sources.

For industry, the most relevant types of electrolysis are alkaline electrolysis (AEC), proton exchange membrane electrolysis (PEMEC) and solid oxide electrolysis (SOEC). In all processes, water is split into its components hydrogen and oxygen. The technologies differ in the choice of membrane and electrolyte.

Alkaline electrolysis (AEC)

In actual practice, alkaline electrolysis is the technology used most frequently. A potassium hydroxide solution (KOH) is used as the electrolyte. The technology is already available on a large scale. Besides the low investment costs and long service life, it has the advantage of using practically no critical raw materials at all. The main disadvantage is the low dynamic response to load changes.

Proton exchange membrane electrolysis (PEMEC)

Compared to alkaline electrolysis, proton exchange membrane electrolysis is a much newer method, but it is also available on an industrial scale. Its main component is the proton exchange membrane. It prevents the two products, oxygen and hydrogen, from mixing, resulting in higher hydrogen purity. PEMEC electrolysis makes fast load changes and a compact design possible. On the downside, expensive catalyser materials are needed.

Solid oxide or high-temperature electrolysis (SOEC)

With this method, the water is fed into the system as water vapour. As a result, it is possible for very high efficiencies of up to 85% to be achieved. The cells operate at temperatures of up to 900 °C. A solid ceramic material serves as the electrolyte. Another advantage of the SOEC is that it is also suitable for the use of CO electrolysis to produce synthesis gas. However, the high temperatures result in low load change capability and high material requirements.

There are numerous technologies available for storing hydrogen. Physical storage systems have a higher gravimetric and volumetric energy density. Material-based storage tanks make storage possible under manageable pressures and temperatures. The two most relevant technologies are storing gaseous hydrogen at a pressure of up to 700 bar and liquid hydrogen at -253 °C in vacuum-insulated tanks. Other technologies include metal hydride storage, LOHC or chemical storage, such as ammonia or methanol.

Hydrogen can be used in a wide variety of industries. The highest demand can be found in industry, as this is where hydrogen is needed because of its chemical properties. Possible applications include the manufacture of ammonia and methanol or steel and cement production. High demand is forecast in the mobility sector as well. For mobility, hydrogen is used wherever electric vehicles are not a viable alternative, such as with high loads and long distances. Included here are aerospace and maritime applications and the transport sector.

Hydrogen consists of only one proton and a single electron. It is therefore the smallest and lightest element, which is why it diffuses very quickly through many materials. Depending on the base material, pressure, temperature and duration of exposure, this can lead to hydrogen embrittlement and thus to premature component fatigue. To ensure that the pipelines remain leak-free and safe, it is essential to select the right material and the right component design for the application.

High-alloy, austenitic chromium-nickel steels with a low carbon content and a high nickel content are best suited for use in hydrogen applications. The low carbon and high nickel content make these steels highly resistant to intercrystalline corrosion and largely prevent hydrogen embrittlement.

Hydrogen embrittlement refers to the penetration and storage of atomic hydrogen in the lattice structure of a material. This causes a reduction in toughness, which can lead to premature fatigue due to cracking or greatly accelerated crack propagation and sudden material failure. Embrittlement caused by hydrogen is highly dependent on the material, pressure, temperature and many other influencing factors.

There is nothing like direct contact. We will gladly take the time for a personal discussion and answer your questions individually.

Please send us your inquiry using our contact form and we will then contact you immediately.

Visit us at our exhibition booth!